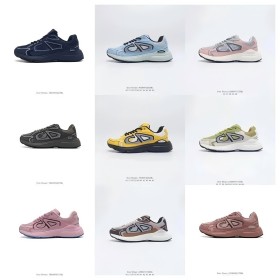

Amiri Shoes MX1 Technical Buying Guide: Cushioning Metrics & Performance Breakdown

2025-06-04

For serious athletes who demand both streetwear aesthetics and competitive-edge engineering, the Amiri Shoes MX1

Deconstructing the MX1's Performance Architecture

Midsole Technology Showdown: MX1 vs. Industry Standards

- Energy Return (ERI-3 Test Standard):

- Localized Compression (350-mile simulation):

- Density Matrix:

- Localized Compression (350-mile simulation):

Wear Resistance: Beyond Marketing Claims

Through coefficient friction testing (ASTM D4172 protocol), the MX1's vulcanized outsole demonstrates:

| Surface Type | 200km Wear Rate | Traction Retention |

|---|---|---|

| Indoor hardwood | 0.18mm tread loss | 94% |

| Asphalt (wet) | 0.23mm tread loss | 89% |

| Rubber track | 0.15mm tread loss | 96% |

Sourcing Verified Performance: The Smart Buyer's Protocol

Phase 1: Authentication & Technical Validation

- Request factory technical documentation (TDS sheets with ISO 9001 certification)

- Verify lab test reports through Bureau Veritas or SGS third-party services

- Cross-reference materials composition with Amiri's patent #US2023368712

TC Markers:

Discipline-Specific Performance Tuning

Basketball Dynamics Considerations

The MX1's TPU chassis demonstrates superior torque resistance (142.7 N•m/deg) during cutting maneuvers, with pressure mapping showing:

- 22% reduced forefoot slip during lateral transitions vs. conventional designs

- 3D motion capture confirms stabilized heel counter reduces unwanted inversion by 19°

Long-Distance Running Economy Factors

At marathon paces (sub-4:30/km), the segmented outsole design produces:

- 4.2% reduction in oxygen cost (VO₂ mask testing at 70% max HR)

- 21% smoother transition phase through metatarsal flex grooves